The reason for good sliding performance of ice relative to metal are a mystery and deserves attention to assist the clearance of snow from metal roofs. The proposed research will take a closer look to determine the factors that improve the sliding performance of metal-ice couples. This is a new strategy that assists clearance of snow from metal roofs – a continuation of the theme from self-cleaning windows – thereby removing the danger of falling snow or ice onto pedestrians. The reasons for good sliding resistance of ice relative to metal are unknown and so this research project will simultaneously make a contribution to science with an application for the community.

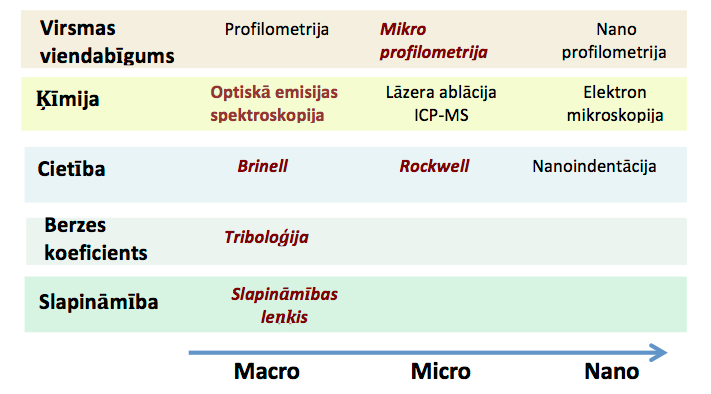

A range of methods will be used for measuring material characteristics at the macro, micro and nano-level. Attention will be directed to surface uniformity, chemistry, hardness, co-efficient of friction and wettability on polished and abraded steel. The techniques shown in red and bold italic represent non-destructive tests – methods that leave the material undamaged, Fig 1. Non-destructive macro, micro and nano-level tests will be applied to polished steel to show how the level of examination will reveal different information. This is useful information when a method needs to be developed to characterize a material for defects or surface quality.

Fig. 1. Material and surface characteristics at the macro, micro and nano-level.

To provide the best background, the first step will evaluate the influence of the metal on the ease at which metal and ice move relative to each other. Metals with different microstructures will be studied at the macro, micro and nano-level and the ease of sliding will be determined. The detailed analysis will show the influence of chemistry, grain size, hardness and surface uniformity on the co-efficient of friction and wettability. This microstructure-property relationship will be extended to see the relationship with sliding performance. The combination of information on materials characteristics and performance represents the materials engineering dependency of performance on the microstructure and properties. This will provide useful information to improve the quality of roofing metals. Very little has been published in the scientific literature about the connection between materials characteristics and sliding performance and so represents a meaningful contribution to the field.

The second activity involves establishing a test for measuring the ease of relative movement between ice and metal. Optical sensors will be placed at the start, at the end and in two intermediate locations to measure the speed of a metal sample on an ice track, and changes during the run. Testing will be conducted in a cold room. The angle of the track can be similar to that found on buildings in Riga and small towns adjacent to roads with a pedestrian walkway underneath. This will provide the first test rig to evaluate the ease of ice to slide on metals with different composition and surface finishes. The role of zinc plating on the change in sliding characteristics will also be considered to makes a useful contribution to the theme of safe buildings. The contribution to science will be made with the influence of material characteristics on the ease of snow and ice movement on buildings.

The 3rd activity will establish a correlation between the sliding performance of a metal on a short laboratory track, a larger laboratory circular track and a long track in the field. Middle-length ice tracks are located at the Technical University of Munich and the Frauenhofer Institute for Mechanics of Materials. Contact will be made to facilitate testing of metal that can be compared to both the laboratory ice track and a long ice track. The benefits of testing on the laboratory track will be established. The comparison of a metal-ice couple with greater friction and lower friction will be compared. This will assist in answering the question of how friction plays an important role once ice starts moving on a metal roof. An unconventional approach will involve the study of different surface roughness on the slideability of metal relative to ice.

The fourth task will be to determine the factors that influence the relative movement of the ice/metal coupled pair. Surface will be prepared with different technologies to offer a range of metal surface. A magnetic or ultrasonic field, a laser and chemico-vacuo conditions will be applied to create changes in the microstructure and topography of the metal surface. The metal modified with five different conditions will be characterized for topography and microstructure using the range of testing techniques shown previously. The microstructure will be assessed for changes in chemistry, grain size, crystallite size, crystal orientation and the affect on hardness determined. This will show the changes that are possible with the different treatments and the influence of relative sliding between ice and metal.

The fifth task will involve the community in brainstorming activities to provide the worst and the best relative sliding between metal and ice. High school students will be invited to participate, and funding will be sought from the Riga City Council to involve the high school students in a socially responsible research project. This will tap into the ideas of many that can be awarded to capture “out-of-sight” approaches to solve a problem. Other skills will be possibly incorporated such as the ability to measure the angle of rooftops at ground level – a skill used by ancestors in Latvia for measuring the height of different objects from the ground. The funding from this project can thus be leveraged many times to activate more people by engaging the community and provide a united effort to address challenges placed on the community. The theme of safety will be appreciated by members of society and lead to thinking about sliding on icy roads. The impact of this study can permeate to driver safety and even be captured by those involved in winter sports that need a better sliding performance between the material surface and the underlying ice.

Z. Butans, K. A. Gross, A. Gridnevs, E. Karzubova. Road safety barriers, the need and the impact on road traffic accident mechanism. 2nd International Conference “Innovative Materials, Structures and Technologies, September 30.- October 2., Riga, Latvia. (

Z. Butans, K. A. Gross, A. Gridnevs, E. Karzubova. Road safety barriers, the need and the impact on road traffic accident mechanism. 2nd International Conference “Innovative Materials, Structures and Technologies, September 30.- October 2., Riga, Latvia. ( J. Lungevics, J. Zavickis, L. Pluduma, K. A. Gross. European Material Research Society (EMRS) Conference “EMSR Fall meeting 2015”, 15.-18.09.2015, Warsaw, Poland. (

J. Lungevics, J. Zavickis, L. Pluduma, K. A. Gross. European Material Research Society (EMRS) Conference “EMSR Fall meeting 2015”, 15.-18.09.2015, Warsaw, Poland. (

E. Jansons, J. Lungevics, J. Rudzutis, K. A. Gross, Use of inclined plane with additional time measurements for investigating surface slidability on ice, The 12th International Conference Mechatronic Systems and Materials 2016, 3.-8.07.2016, Bialystok, Polija,

E. Jansons, J. Lungevics, J. Rudzutis, K. A. Gross, Use of inclined plane with additional time measurements for investigating surface slidability on ice, The 12th International Conference Mechatronic Systems and Materials 2016, 3.-8.07.2016, Bialystok, Polija,  J. Lungevics, K.A. Gross, Modification of metal surfaces for achieving a lower friction and wear, Riga Technical University 57th international scientific conference. Session: National Research Project “Inovative materials un intelligent technologies for safety in the environment, “IMATEH”, 17 October 2016, Rīga, Latvija

J. Lungevics, K.A. Gross, Modification of metal surfaces for achieving a lower friction and wear, Riga Technical University 57th international scientific conference. Session: National Research Project “Inovative materials un intelligent technologies for safety in the environment, “IMATEH”, 17 October 2016, Rīga, Latvija

44th Leeds Lyon Symposium on Tribology, 04.-06.09.2017, Lyon, France

44th Leeds Lyon Symposium on Tribology, 04.-06.09.2017, Lyon, France